Bronze bushings for Hydroelectric

According to the hydropower station, the use of natural water flow and regulation capacity can be divided into two categories.

- Run-of-River Hydropower Station: no reservoir or very small reservoir capacity, no or very little regulation of natural water flow.

- Storage Type Hydropower Station: reservoirs with a certain capacity, with different regulating abilities for natural water flow.

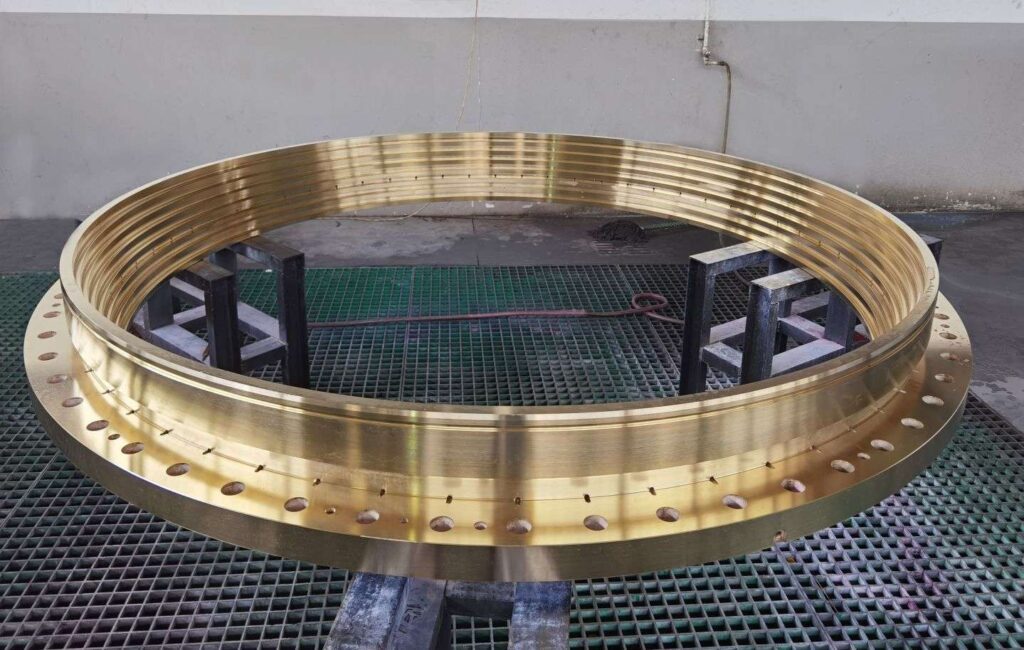

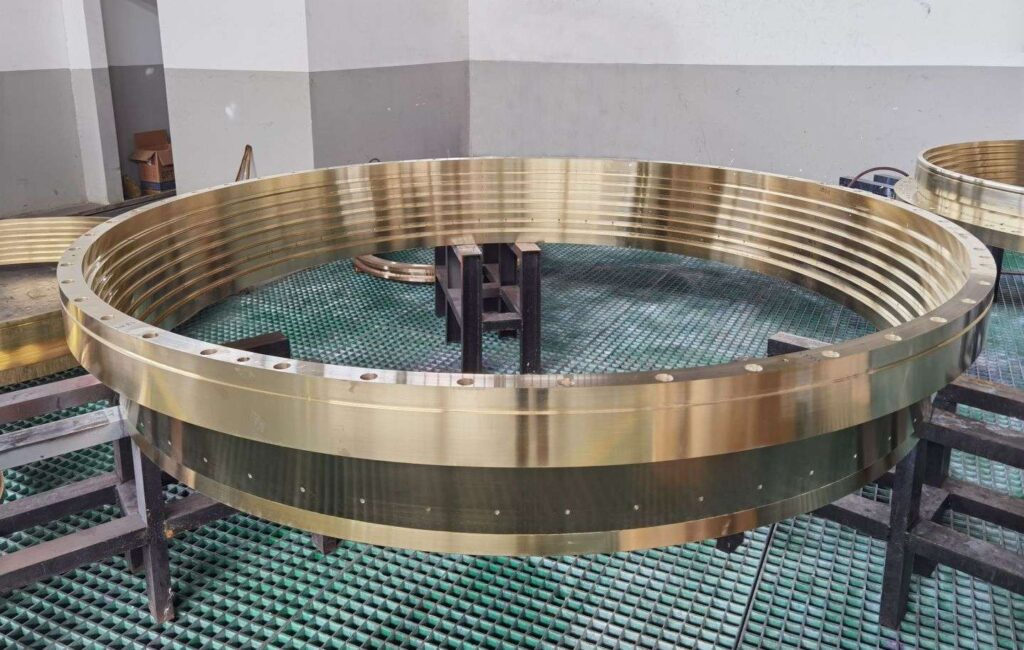

- Our aluminum bronze sealing rings are professionally used in pumped storage hydropower stations, with material CuAl10Fe3, high strength, wear resistance, and corrosion resistance.

- We have the ability to produce products φ 1.5m-6m, the only manufacturer you can find for super large-size bronze bushings!

Table of Contents

- Download this page as a PDF

To save you time, we have also prepared a PDF version containing all the contents of this page.

Why choose Jedbushing.com?

Our expertise in sealing copper rings for hydroelectric power plants is the highest grade available and our secret is in superior quality and professional service. We have sold countless tons of products worldwide over the past 20 years.

Completing a large-size seal ring is very difficult, and it’s not just about the mold. Every hurdle not done properly, such as smelting recipe, temperature, casting speed, mold release, and finishing can scrap this product and start over. Jedbushing is the brand you can trust.

- We are ISO certified and have an environmentally certified smelting and casting factory.

- We have many successful experiences to share to solve your problems.

- Every product is tested by UT and PT to meet your requirements.

- Samples are not available due to oversized sizes. However, we can provide material test reports.

- Faster checkout; we ship to you ASAP.

Want to know how we can do business? Let’s talk about it!

Use our sealing rings to run hydroelectric plants better!

We have a wide range of products for the hydropower industry. Making Jedbushing your amazing seal ring supplier, here are some of our best-selling items.

The Best Quality. Our sealing brass rings allow you to be satisfied after running one hydroelectric unit and immediately turn on another hydroelectric unit.

Stay Away From Maintenance. The components of a hydropower unit have strict requirements, and as seals, our only requirement is a tight fit and no leaks.

One-time Casting. Only products that have been successfully cast in a single pour qualify as hydropower plant seals, and we do not accept any cracks.

Easy to Install. We make them strictly according to the drawings to meet the requirements without causing trouble for a big project like a hydropower plant.

Long Service Life. Unlike other copper sleeves for different applications, copper rings for hydropower plants need to be sealed and do not require harsh wear resistance, so they all have a long service life.

Trusted Materials. the material ratio is reported, so there will be no situation that the hydro unit will stop operation due to breakage.

Let Jedbushing be your bronze casting supplier. If you’re looking for sealing rings or slip rings, our products are the key. With our products, opening a hydroelectric project has never been easier.

Estimated wholesale price

Payments made to Jedbushing products are secure, and the following is a summary of the costs you will incur.

Sample Product Fee

In case you need a bronze sample, pay the material amount and shipping costs. But our proposal is changed to a free test report.

Shipping Fee

This is the amount you will pay for shipping the product from the factory to your doorstep. Jedbushing provides you with any kind of convenience.

Mould Fee

We have several hundred sets of 60mm-5m bushing molds. But this is not always suitable for new products, so if the size doesn’t match, you need to make a new mold.

40% T/T & 60% Final Fee

You can decide to either pay the full amount or pay 40% of the full payment for the wholesale. Complete your payment within a certain period and receive the products you ordered for.

Estimated manufacturing and shipping times

We work quickly. With more and more customers approaching us, we have no other choice but to prioritize speed. Let’s take a look at the entire process of manufacturing and shipping.

1. Design and casting time

Feed inspection, smelting, casting, and sample retention, this is the beginning of all bronze castings.

2. Precision machining

Rough turning first, then finish turning according to the drawing. We finish them in a 24-hour constant temperature and humidity environment.

3. Inspection and testing time for all products

A series of inspection processes such as material analysis, UT, PT, hardness, spectral analysis, burr, CMM, etc.

4. Sea and land transportation time

Once the products arrive at their destination, you will receive an alert. You can plan how to collect your shipped goods.

Is It Good As Other Bearing? Things you Need to Know

To save you from worries, here are some facts you need to know about our bushing:

Is it hard to cast large size sealing copper rings?

It is really difficult, and we have gone through hundreds of debugging and experiments to conclude the successful experience. At present, the one-time casting success rate of 1.5m to 3.5m diameter is 100%, and the success rate of 3.5m to 5m is 85%.

Are your bushings a complete replacement for bearings?

Yes, they can. For different industries and site environments, we produce products with different hardness, strength, corrosion and wear resistance characteristics. We also have bimetallic bearings to save cost and ensure quality at the same time.

How long does it take to produce?

Sealing rings for the hydropower industry are very special because of their large size and are basically not in stock. The typical time from material to delivery is 15-60 working days.

How do you do quality inspection for such a large product?

We have inspection process: raw materials, smelting formula, spectral test, CMM dimensional inspection, PT/UT inspection, factory inspection. You can control every step.

Service Products

We have a large selection of plain bearings for various applications. With us you can order your products according to your own drawings and specifications or you can choose from our large and wide standard selection. In addition, our short lead times and good logistics makes us an efficient and reliable partner.

Aluminum bronze bearings have high hardness, high strength, corrosion resistance and high wear resistance, and are often used in bearings, valves, turbines, nuts and other parts; aluminum bronze also has a unique ability to prevent seawater breeding, and is often made by the shipbuilding industry. propeller.

C95400(ZCuAl10Fe3) cast copper alloy has high mechanical properties, good wear resistance and corrosion resistance, can be welded, not easy to braze, and large castings can be prevented from becoming brittle by air cooling at 700 °C. C95400(ZCuAl10Fe3) cast copper alloy is used for important castings that require high strength, wear resistance and corrosion resistance, such as bushings, nuts, worm gears and pipe fittings that work below 250 °C.

- GB/T: ZcuAl10Fe3

- BSEN: CC331G

- Hardness: 100-130HB

- Friction Coefficient: <0.18

- Elasticity Modulus: ≈110KN/mm²

- Tensile Strength: 490-580Mpa

- Operating Temperature: <250℃

C95500(ZcuAl10Ni5Fe5) has high strength and good wear resistance. It is used for high-strength screws, nuts, copper sleeves, sealing rings, etc., and wear-resistant parts. The most prominent feature is its good wear resistance.

Because aluminum bronze containing iron and manganese has high strength and wear resistance, it can increase the hardness after quenching and tempering, and has good high temperature corrosion resistance and oxidation resistance. Corrosion resistance in the atmosphere, fresh water and sea water very good

- GB/T: ZcuAl10Ni5Fe5

- BSEN: CC333G

- Hardness: 140-170HB

- Friction Coefficient: <0.18

- Elasticity Modulus: ≈120KN/mm²

- Tensile Strength: 490-580Mpa

- Operating Temperature: <250℃

THE PROCESS IS EASY!

JEDBUSHING is specific to the customer. All below process is what you can expect from us.

Inquiry/Proposal

Fully communication for requirements helps getting optimal proposal. bronze bushing solution is provided within 24 hrs. It takes longer for drawing considering bushing complexity.

Visit

Trip to us helps you understand who you are working with, while the visit to a real production line plant would be amazing and you would know what you can expect from us

Fabrication/Test

We will arrange manufacturing once the advance payment received. Lead time pends on product.

FAT

You are warmly welcomed to witness Factory Acceptance Test before delivery. If there are materials samples are available, test with product can be arranged.

Packing/Shipping

Safe packing suitable for long distance transportation is provided once shipment approval. Shipment is arranged together with forwarder.

Customs Clearance

When the goods arrive at the destination port, you can pick up goods after Customs Clearance done

Installation/ Commissioning

After the goods arrive at the site, on-site installation and commissioning can be arranged if necessary with cost.

Support

We provide lifelong service and support for the equipment and you only focus more on your business.

WE'D LOVE TO HEAR FROM YOU

Customizing your Bushing

You will get accurate bushing solution in 24 hours if info listed below are provided. We also would like to help on with our experience if you have no detailed plan for the time being.