Bimetal bearing is a kind of self-lubricating bimetal bearing. It is based on high load capacity, high performance, and low-carbon steel backing, and the surface is sintered with lead bronze alloy. After several high-temperature sintering and dense rolling, it becomes a copper-steel bimetallic strip. Rolled, suitable for bushings, thrust washers, etc. bearing medium speed and high impact load market.

The balance axle bushings of heavy-duty vehicles all use bimetal plain bearings, which are a wide range of high-load low-speed metal motion bimetal bushings. In high sliding performance, it has particularly good self-lubricating performance in the absence of a lubricating medium and water as the medium. It is suitable for bimetal casting materials, corrosion-resistant bearings with high sliding speed, and bearings for crushers, water pumps, and cold rolling mills. Piston pin sleeves with loads up to 70MPa.

Features and Applications of Bimetal bearings

Bimetal Bearings Features

The product has the advantages of good wear resistance and so on. It is especially suitable for occasions such as medium speed and medium load and low speed and high load.

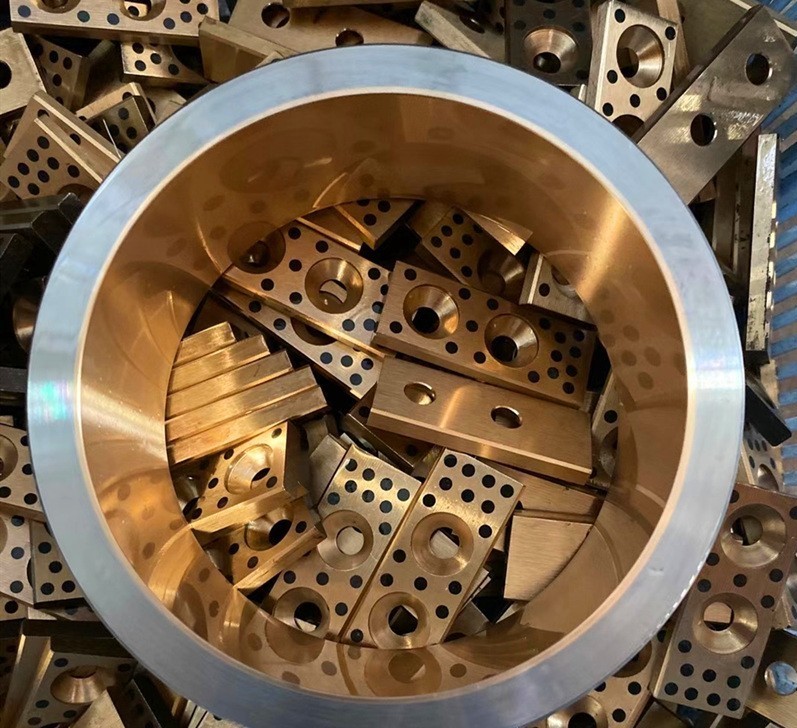

Through special technological means, various oil grooves, oil pockets, and oil holes can be processed on the friction surface, so as to adapt to the use under different lubrication conditions.

Metal base inlaid self-lubricating bimetallic bearings are novel lubricating bimetal bushings that combine the characteristics of metal plain bearings and self-lubricating bimetal bushings. It has the characteristics of high bearing capacity, impact resistance, high-temperature resistance, strong self-lubricating ability, etc.

It is especially suitable for heavy loads, low speed, reciprocating or swinging, and other occasions where it is difficult to lubricate and form oil film, and it is not afraid of water and other acid erosion. and scour.

Bimetal Bearings Applications

Products have been widely used in automotive engines, chassis, motorcycle clutches, gear pump wipers, lifting equipment, and other fields.

Mainly widely used in balance axle bushings, gaskets, automobile steel plate bushings, internal combustion engine main bushes, connecting rod bushings, rocker arm bushings, oil pump side friction plates, medium and small power internal combustion engine bearing bushes, train engine metal bearings bushes, air Press bushings, refrigerators, etc.

Since the base body is stable in low carbon steel material, the machining accuracy of the outer diameter of the shaft sleeve is guaranteed, and after the product is installed in the seat hole, it does not need to be fixed by screws, and the phenomenon of the outer circle can be prevented by relying on interference fit.

The chemical composition of the inner surface alloy layer can be changed to meet the requirements of different metal bearings pressures, different operating temperatures, and different sliding speeds. The friction surface is designed with different structures of oil grooves and oil pockets in production to meet the requirements of different refueling methods and prevent bites.

Materials of bimetal bearings

Base material: low carbon steel, the outer surface can be plated with copper or tin for corrosion resistance.

Inner wall copper layer: The inner wall copper layer is mainly made of CuSn6Zn6Pb3 or CuSn6.5P0.1 two kinds of tin bronze and two kinds of lead bronze CuPb10Sn10 or CuPb24Sn, a total of four types of copper layers and ALSn20Cu high-tin aluminum alloy layer. Copper layer material.

The standard thickness of the alloy layer is 0.25mm-0.3mm, and the non-standard alloy layer of any thickness can also be sintered according to customer requirements.

The difference between bi-metal bearings and rolling/needle bearings

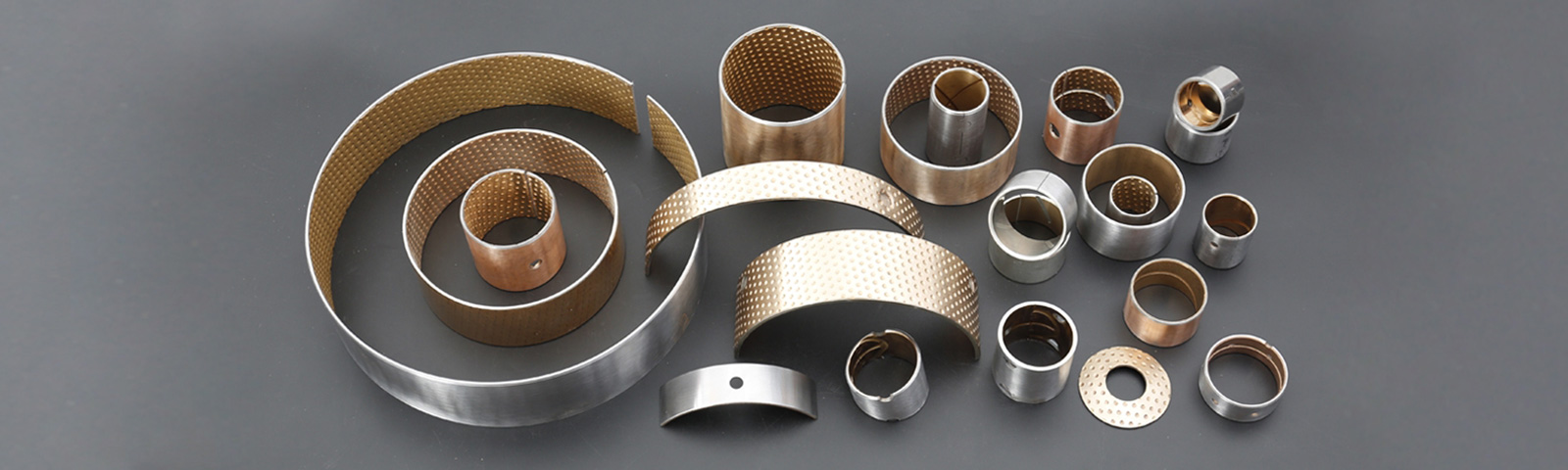

Bimetal bearings bushings composed of different components (metals, plastics, solid lubricating materials) are called bi-metal bearings. Bimetal plain bearings themselves are sliding bearings. Bi-metal bearings are also called bushings, bushes, or sleeve bearings, usually Cylindrical with no moving parts.

Bimetal Bearings Standard Configurations

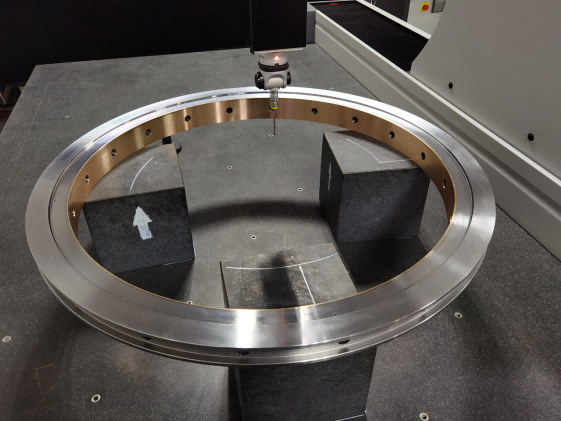

Standard configurations include cylindrical bearings for radial loads, flanged bearings for radial and light axial loads, shims and shims for heavy axial loads, and sliding plates of various shapes. Custom designs are also available, including special shapes, features (slots, holes, notches, tabs, etc.), and dimensions.

Bimetal bearings bushings are used for sliding, rotating, oscillating or reciprocating motion. Sliding applications are often used as plain bearings, bearing pads, and wear plates.

Various types

The sliding surfaces are usually flat, but can also be cylindrical, and always move linearly, not rotationally. Rotational applications involve cylindrical faces and one or two directions of travel. Oscillating and reciprocating applications involve flat or cylindrical surfaces, that travel in both directions.

Bimetal bearings constructions can be solid or split butt (coiled bearings) for easy installation. It is critical that bimetal bearings are matched to the application. High loads require bearings with increased contact area and higher load carrying capacity.

Compared to oil and grease-lubricated bearings, solid lubricant bearings are designed to operate at higher temperatures. High-temperature applications require special lubrication measures to minimize heat build-up and friction.

Bimetal bearings are manufactured in different constructions. Product selection depends on operating conditions and performance requirements.

Types of bimetal bearings low friction materials

Bimetal Bearings Bushings consist of a metal backing (usually a steel or copper backing) on which a porous copper interlayer is sintered, impregnated with Teflon and additives to obtain a running surface with anti-friction and high-wear bushing properties. These bearings can be run dry or externally lubricated.

Manufacture high load capacity

Bimetal bearings can also be made of engineering plastics, which have excellent wear resistance and low friction properties, and are widely used in dry friction and lubricated working conditions.

Injection molding can be designed into almost any shape and made of various resins mixed with reinforcing fibers and solid lubricants. These bearings have excellent dimensional stability, low coefficient of friction, and good thermal conductivity.

Manufacture machine tools

Fiber Reinforced Composite Bearings are another form of bimetallic bearing, filament wound, fiberglass impregnated, epoxy abrasion resistant low friction bearing linings constructed with a variety of backings.

This construction allows the bearing to withstand high static and dynamic loads, and the inherent inertness of the material makes the product ideal for use in corrosive environments.

Monometallic, bimetallic, and sintered composite bearings are designed for overland and subsea industrial applications with a slow motion under high loads. Lubricant-impregnated/solid copper bearings provide maintenance-free performance in high-temperature applications, while monometallic and bimetallic bearings are designed for lubricated applications.

Bimetal bearings and rolling/needle bearings cannot be used interchangeably.

Rolling bearings, due to their complex multi-component design, precise structure, and precise installation, are often much more expensive than bi-metal bearings.

Rolling bearings are more suitable for applications requiring precise shaft position and/or extremely low friction. Due to their larger contact area and adaptability, can provide higher load bearing capacity and tolerance of high shock loads and end concentrated loads.

Bimetal bearings can compensate for the dislocation better than some rolling bearings, so as to reduce the impact of the concentrated load at the end.

The bimetal bearings adopt an ultra-thin single-piece design, which can reduce the size of the shell and save space and weight to a large extent. It has stronger resistance to reciprocating motion, which can prolong the bearing life.

The bimetal bearings will not suffer from wear and damage caused by the sliding of rolling elements when running at high speed and under low load and have excellent damping performance. Compared with rolling bearings, which have no moving parts inside, so the operation is quieter, and the speed is almost unlimited under a properly lubricated system.

The installation of the bimetal bearings is simple, only need to machine the shell, and it will hardly cause any damage to the accessories compared with the rolling bearing.

Compared with standard rolling bearings, non-metal composite bearings have stronger corrosion resistance. Bimetal bearings can run dry without the cost of additional lubricant systems, lubricants, and equipment downtime for maintenance.

Bimetal bearings can run dry at high temperatures and in the presence of contaminants.

Helping the world’s agricultural machinery industry to upgrade

Supply engine bearings bushings

In the key parts of agricultural machinery, there are sliding bronze sleeves and bimetal bearings everywhere. Every busy season, the special bearings for the agricultural industry will shoulder the mission of “not lying down” in the harsh environment of high temperatures, dust, and high speed, and contribute to the upgrading of this industry.

Example: The cotton picking operation environment is dusty, and the cotton picking machine needs to carry out a high-intensity continuous operation while ensuring the cleaning rate. With decades of accumulated experience in the agricultural industry,

Jiaerda has determined the root cause of the problem: the harsh environment of high temperature, high pollution, and high speed. Reduced sliding bushing/bearing failure rates.

Trust sport

Each field operation is unique due to differences in crop species, field size, geographic location, climate, and soil structure. In addition to the cotton picker industry.

Jiaerda Machinery also provides customized sliding bushing/bearing solutions for various types of agricultural machinery, giving full play to the high bearing capacity, strong sealing, and maintenance-free advantages of bearings to ensure high efficiency of agricultural machinery, Reliable operation.

Impregnated bimetal bearings

The porous material is used as the matrix and impregnated with solid lubricant to form solid-lubricated impregnated bimetal bearings. The solid lubricant stored in the bearing pad continuously supplies the solid lubricant to the friction surface as the bearing pad wears. A typical composite bearing is made of carbon graphite as the base material, impregnated with soft metal, polytetrafluoroethylene, or inorganic (BaF2).

The methods of impregnation

- Vacuum impregnation is carried out with the impregnated material in a molten state.

- Use the sclerosing liquid as a carrier, in which the impregnated material is placed for impregnation.

- The volatile liquid is used as the carrier, the impregnating substance is dispersed therein for impregnation, and then the liquid is volatilized.

- Impregnation is performed after vaporizing the impregnated material. Impregnation not only provides lubrication but also increases the strength of the matrix material.

Bimetal Bearings VS Engineering Plastic bushings

The bearings currently used can generally be divided into rolling bearings and sliding bimetal bushings

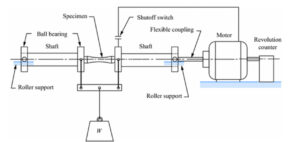

The working principles of rolling bearing and sliding bushings can be distinguished by their names. The friction that occurs when rolling bimetallic bearings work is rolling friction, while the sliding friction occurs when sliding bushings work; the magnitude of rolling friction mainly depends on the manufacturing accuracy, and sliding friction The magnitude of the bearing friction mainly depends on the material of the bearing sliding surface.

Sliding bimetal bushings generally have self-lubricating working surfaces; sliding bearings are divided into non-metallic sliding bushings and metal sliding bushings according to materials.

Non-metallic sliding bushings are currently mainly plastic bushings. Plastic bushings are generally made of engineering plastics with better performance; more professional manufacturers generally have engineering plastics self-lubricating modification technology, through fibers, special lubricants, glass

The self-lubricating enhancement and modification of engineering plastics are carried out to achieve certain performance, and then modified plastics are processed into self-lubricating plastic bearings by injection molding. At present, the most used metal sliding bearing is the three-layer composite bearing. This kind of bearing is generally based on carbon steel plates.

Through sintering technology, a layer of spherical bronze powder is first sintered on the steel plate, and then a layer of spherical copper powder is sintered on the powder layer. 0.03mm PTFE lubricant; the main function of the middle layer of spherical copper powder is to enhance the bonding strength between the steel plate and PTFE, of course, it also plays a certain role in bearing and lubrication during work.

Inner wall material performance:

CuPb24Sn4

It has high fatigue strength, bearing capacity, and impact resistance, but due to the high content of lead in the alloy and the high specific gravity, it is easy to cause lead segregation, which reduces the wear resistance of the bushing/engine bearings and also makes the alloy layer and the steel. The bond strength of the back is reduced, and the cost of this copper layer is higher for bearings used in high-speed, swing, and rotating wage conditions.

CuPb10Sn10

It has high fatigue strength and bearing capacity, good lubricating performance, good wear resistance and corrosion resistance, suitable for bearing with medium load, medium to high speed, and large impact load rolls used in mechanical equipment Bearings, sliding bushing with a high surface pressure of washers and side pressure, such as rolling bearings, vehicle bearings, thrust washer, steel backing production bimetal bearing bushes, cylindrical bushes, piston pin sleeves, friction plates, thrust washers, etc.

CuSn6Zn6Pb3

Good wear resistance and corrosion resistance, easy processing, good casting performance, and air tightness, wear-resistant and corrosion-resistant parts that work under general load and moderate sliding speed, business range such as turbines, motors, compressors, piston clutches, connecting rod bushings, rocker arm bushings, thrust washers, etc., which are currently used in large quantities.

CuSn6.5-0.1

Lead-free bimetallic bushings are widely used in balance axle bushings, gaskets, internal combustion engine main bushes, connecting rod bushings, rocker arm bushings, oil pump side friction plates, medium and small power internal combustion engines for heavy vehicles Bearing bushes, engine bearings, train engine bearing bushes, thrust washers, air compressor bushings, refrigerators, etc.

AlSn20Cu

It has moderate fatigue strength and bearing capacity, good corrosion resistance, and sliding properties. It can be matched with flexible shafts and is often used as bearing bushes of medium and small power internal combustion engines, thrust washers, train engine bearing bushes, air compressor bushings, etc. It is the best product to replace babbitt.

Jiaerda Machinery

Our company address is located in Zhejiang, China, the company has an annual output value exceeding 200 million, and it has been mounting. manufacturing range of copper bushings/plates/ sliding bearings/machined parts, etc., regular products are in stock.

The company has a business range covering domestic and overseas markets, supports factory reports, and supports third-party testing. In addition to manufacturing copper products, my company also produces heat exchangers, also called coolers, which are also sold to the overseas world business market.