We have studied several development directions: including the bimetal bearing market, copper raw materials, and environmental protection, and believe that bimetal bearings will be the mainstream copper bushings in the future.

⦁ Product price issues: Non-ferrous metal prices have been rising since 2019, with particularly exaggerated fluctuations in 2021 and 2022, which we found could lead to out-of-control costs for companies and the market environment.

⦁ Overall quality problem: Also due to the drastic changes in all factors such as raw material prices and labor costs, we found that the quality of a small number of factories has declined. This will be a butterfly effect because it will affect the life of the supporting equipment and the end-use environment. life.

⦁ Global environmental issues: If the overall material is made of copper alloy to cast sliding bearings, the demand for non-ferrous metals such as copper is huge (the copper content of each copper sleeve is basically above 85%). We investigated copper mines, and non-ferrous metals The over-exploitation of mines is very serious, which also leads to a series of environmental problems.

What are the advantages of Bimetal Bearings?

To put it simply and directly: the steel-copper composite copper sleeve can help you save costs while maintaining the same performance. We have been developing and upgrading the manufacturing process for the past 10 years. Industry discussions, market research, and customer feedback are all inseparable.

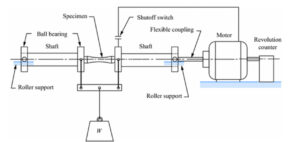

⦁ The bimetal bearing uses steel as the back layer and copper alloy as the wear-resistant layer. The casting process is used to combine the metallurgical molecules of the two materials into one

⦁ To achieve both the strength of steel and the wear resistance of copper alloy, the advantages of both materials are used to the extreme.

⦁ The thickness of the wear-resistant layer of the bimetal bearing is about 1-2mm, and the rest are replaced by steel billets

⦁ It can effectively save copper alloy resources and reduce the comprehensive risk caused by the unstable price of non-ferrous metal materials.

⦁ Cost comparison: The cost of bimetal bearings can be reduced by about 10%-30% compared with the overall copper alloy bearings.

⦁ Special process requirements: Bimetal bearings are generally steel outside and copper alloy inside. Special use cases also have steel inside and copper alloy outside.

What qualification certificates do you have for Bimetal Bearings?

⦁ In 2010, began to develop the manufacturing process of bimetal bearing composite weekly test

⦁ In 2015, the invention patent of bimetal bearing was authorized

⦁ Over the years, it has won more than 20 invention patents and utility model patents for composite manufacturing of steel and copper.

What are your popular products for bimetal bearings?

Bimetal bearings mainly implement the JB/T 7921-95 standard and then use the company’s research and development technology on the basis of this national standard. At present, it is mainly used in wind power, hydropower, hydraulic, power, compressor, and other industries.

The product has the wear resistance, hardness, and corrosion resistance of the inner wall copper alloy, and has the rigidity, hardness, extrusion resistance, and high-temperature resistance of the outer wall steel alloy.

⦁ Air compressors such as crosshead bearing connecting rod bushing, etc.

⦁ Hydraulic press such as tie rod bushing, guide bearing, etc.

⦁ Wind turbines such as floating oil distribution rings, etc.

The main material of the steel back layer of the product is low-carbon steel. The main material of the wear-resistant layer: the American label is attached to the side

Use Cases for Bimetal Bearings

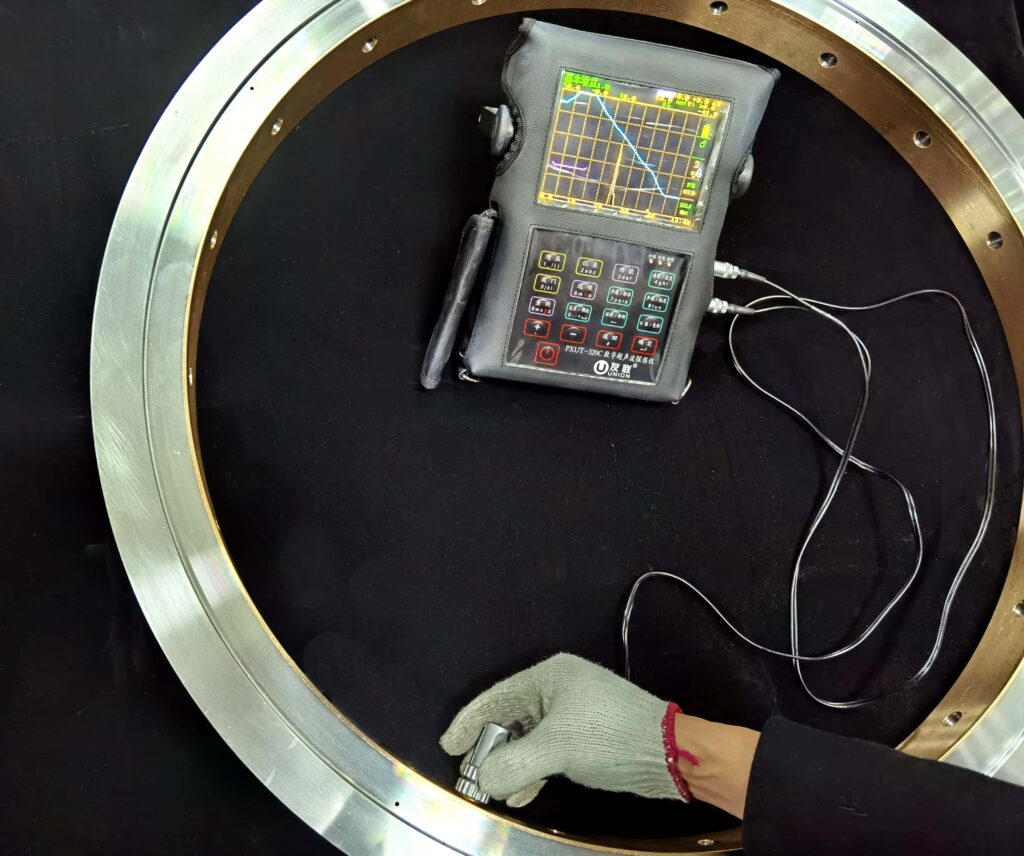

Process Inspection of Bimetal Bearings