Copper alloys are divided into brass and bronze, etc. according to their composition. According to the chemical composition, brass is divided into two kinds of ordinary brass and special brass.

Ordinary brass is a copper-zinc binary alloy. It has good plasticity and is suitable for plates, bars, wires, tubes, and deep-drawn parts, such as condensation tubes, heat sink tubes, and mechanical and electrical parts.

Obtain higher strength

In order to obtain higher strength, corrosion resistance, and good casting performance, special brass is formed by adding aluminum, silicon, manganese, lead, tin, and other elements to the copper-zinc alloy. Such as lead brass, tin brass, aluminum brass, silicon brass, manganese brass, etc.

JIAERDA tin bronze contains 3% to 14% tin, in addition to phosphorus, zinc, lead, and other elements. It is corrosion-resistant, wear-resistant has good mechanical properties and process properties can be well welded and brazed, and does not produce sparks when impacted.

Tin bronze’s elastic strength

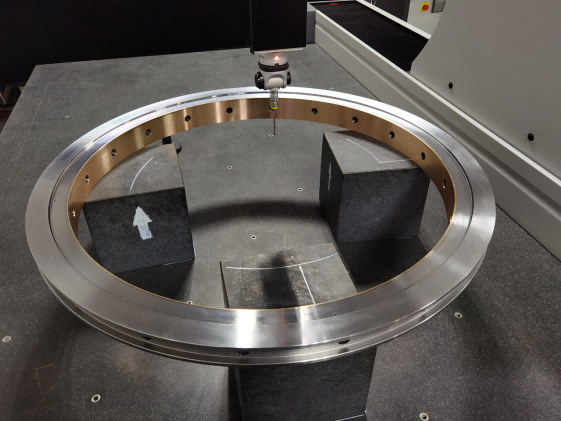

JED tin bronze is a copper-based alloy with tin as the main alloying element called tin bronze. Most of the tin bronze used in industry has a tin content between 3% and 14%. It is widely used in shipbuilding, chemical, machinery, instrumentation, and other industries, mainly for the manufacture of bearings, bushings, and other wear-resistant parts and springs and other elastic components, as well as anti-corrosion, and anti-magnetic parts.

Tin content

- Tin bronze with a tin content of less than 5% is suitable for use in cold processing.

- Tin bronze with a tin content of 5% to 7% is suitable for hot processing.

- Tin bronze with a tin content of more than 10% is suitable for casting.

Tin bronze material high-precision processing, the tool as far as possible using single crystal diamond, and effective access to the lattice position. When sharpening the geometric angle of super-finishing tools, wide edges and large front angles can be used. For all moving parts of the machine tool, transmission pay accuracy must be higher than the machining accuracy.

The corrosion resistance of tin bronze

JED tin bronze has good corrosion resistance, is better than ordinary steel, and is better than aluminum in an alkaline atmosphere. The potential sequence of copper is +0.34V, which is higher than hydrogen and is a metal with more positive potential. The corrosion rate of copper in freshwater is also very low (about 0.05mm/a).

And copper pipes are used to transport tap water, the wall does not deposit minerals, which is far from the iron water pipes. Because of this feature, copper water pipes, faucets, and related equipment are used in large quantities in high-grade bathroom water supply installations.

Copper is extremely resistant to atmospheric corrosion, and its surface can form a protective film consisting mainly of alkaline copper sulfate, known as copper green. Therefore, copper is used in building roof panels, rainwater pipes, up and downpipes, pipe fittings; chemical and pharmaceutical vessels, reactors, pulp screens; naval equipment, propellers, living and fire-fighting pipe networks; punching kinds of coins (corrosion resistance), decoration, medals, trophies, sculptures and handicrafts (elegant color), etc.

Tin bronze corrosion differences in different environments

Atmospheric corrosion of JED tin bronze alloys Atmospheric corrosion of metal materials depends mainly on the water vapor in the atmosphere and the water film on the surface of the material. Atmospheric corrosion

The speed began to increase sharply when the relative humidity of the atmosphere is called the critical humidity, tin bronze alloys, and many other metals in the critical humidity between 50% to 70%, atmospheric pollution on the corrosion of tin bronze has a significant enhancement effect. In the urban industrial atmosphere of C02, SO2, NO2, and other acidic pollutants dissolved in the water film, hydrolysis occurs, so that the water film acidification and protective film instability.

Decay of plants and exhaust gases from factories

The presence of ammonia and hydrogen sulfide gas in the atmosphere, ammonia significantly accelerates the corrosion of copper and tin bronze, especially stress corrosion.

Copper and tin bronze in different atmospheric corrosive environments, corrosion sensitivity has a large difference. Corrosion data in the general marine, industrial and rural, and other atmospheric environments have been reported for 16 to 20 years. Most Jalda tin bronze for uniform corrosion, a corrosion rate of 0.1 to 2.5μm / a.

Harsh industrial atmosphere, industrial marine atmosphere

The corrosion rate of tin bronze is an order of magnitude higher than that of the mild marine atmosphere and rural atmosphere. The polluted atmosphere can make the brass stress corrosion sensitivity significantly increase. Work is underway to predict the rate of corrosion of tin bronze in different atmospheres based on environmental factors and to classify them in a hierarchical manner.

Melting characteristics of tin bronzes

Harmful impurities in tin bronze are aluminum, silicon, and magnesium, and when their content exceeds 0.005%, the resulting SiO2, MgO, and Al2O3 oxide inclusions contaminate the melt and reduce some aspects of the alloy’s properties.

When melting tin bronze, because the boiling point of zinc is relatively low and has a greater affinity for oxygen, should be deoxidized in the melt before throwing the furnace melting, so that the zinc can be supplemented by deoxidation, thus helping more to avoid the danger of producing SnO2.

High tin bronze alloys

High tin bronze alloys, brass alloys, and bronze alloys are used in steam fittings, pump impellers, high-strength bushings, piston rings, and bearing applications that can be heavy loads.

Tin bronzes are also typically found to be long-life, high-strength alloys that bearing, bushings, and gears, are often used. We have records in our account back office.

Remarks

The website department will count the user demand by the user’s click on the page, or email message. at present we find that different users are interested in the hardness, limit, and applications of the bushings, so the website page will add relevant information such as adding tin bronze impellers.