Coordinate measuring instrument three axes have air brake switch and micro device, can realize the precision transmission of single axis, using high-performance data acquisition system.

Applied to product design, mold equipment, gear measurement, blade measurement machinery manufacturing, jigs and fixtures, automobile mold parts, electronic appliances and other precision measurement

JIAERDA laboratory includes: Composition testing, Mechanical property testing, Friction coefficient testing, Metallographic testing, Three-coordinate measuring and so on.

Hexagon CMM Coordinate Measuring Machine

The concept of coordinates is derived from analytic geometry. The basic idea of analytic geometry is to construct coordinate systems that relate points to real numbers, which in turn allows curves in the plane to be represented by algebraic equations.

It can be seen here that the use of coordinates not only allows geometric problems to be solved algebraically, but also closely links important concepts such as variables, functions, and number and form.

The concept of coordinates has been applied to industrial production to solve a large number of practical problems, and the vast majority of modern measuring instruments have been built on the basis of the principle of coordinate measurement.

The emergence of coordinate measuring machine is the historical necessity of the development of industrialization.

On the one hand is due to the development of automatic machine tools, CNC machine tools and other high-efficiency processing and more and more complex shapes of parts processing need to have fast and reliable measuring equipment and its supporting; on the other hand is due to the development of electronic technology, computer technology, numerical control technology, as well as precision machining technology to provide a technical basis for it.

The emergence of coordinate measuring machine makes the measuring instrument from the manual way to the modernization of automatic measurement of the transformation has become possible.

Unlike traditional measuring instruments which are comparative measurements of the measured and mechanical datums, CMM measurements are actually based on the acquisition and calculation of spatial point coordinates.

Although modern CMMs are much more advanced than the earlier ones in terms of functionality, the basic principle is the same, i.e., a rigid structure is built, which has three mutually perpendicular axes, each of which is fitted with a scale and is defined as the X, Y, and Z axes, respectively.

In order to allow each axis to move, each axis is fitted with air or mechanical bearings. A probing system on the vertical axes records the position of the measurement point at any given moment.

The probing system generally consists of a probe and a contact probe, which makes slight contact with the surface of the workpiece to be measured and obtains the coordinates of the measuring point.

During the measurement process, the CMM converts the measurement of the various geometric elements of the workpiece into the coordinate positions of the points on these geometric elements, and then the software calculates the dimensions, shapes, relative positions, and other parameters of these geometric elements based on the mathematical models of the corresponding geometric shapes.

CMM as a precision, efficient space length measurement instruments, it can realize many traditional measuring instruments can not be completed by the measurement work, its efficiency than the traditional measuring instruments dozens of times or even dozens of times higher.

And CMM is easy to connect with CAD, the results of real-time feedback to the design and production departments, in order to improve product design or production process. Therefore, CMM has replaced and will continue to replace many traditional length measuring instruments.

Thermo ARL Optical Emission Spectrometer

The Thermo ARL Optical Emission Spectrometer (OES) is an analytical instrument used for the elemental analysis of various materials, including metals, alloys, ceramics, and geological samples. It is designed and manufactured by Thermo Fisher Scientific, a leading provider of scientific instrumentation and services.

The Thermo ARL OES operates based on the principle of optical emission spectroscopy (OES), which involves exciting the atoms in a sample and analyzing the characteristic wavelengths of light emitted by those atoms. Here’s a brief overview of how it works:

- Sample preparation: The sample to be analyzed is prepared by grinding it into a fine powder or by creating a solid disk through fusion or pressed powder techniques.

- Excitation source: The sample is introduced into the instrument, where it is subjected to an intense heat source, typically an electrical spark or an argon plasma. This heat source excites the atoms in the sample, causing them to emit characteristic wavelengths of light.

- Optical system: The emitted light from the excited atoms is collected and directed through a series of optical components, such as lenses, mirrors, and a diffraction grating or a polychromator. These components separate the light into its constituent wavelengths.

- Detector: The separated wavelengths are detected by a photomultiplier tube or a charge-coupled device (CCD) detector, which measures the intensity of each wavelength.

- Data analysis: The measured wavelengths and their intensities are compared against reference data stored in the instrument’s software or external databases. This comparison allows for the identification and quantification of the elements present in the sample.

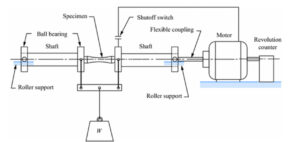

Tensile Testing Machine

A tensile testing machine, also known as a universal testing machine or a materials testing system, is a laboratory instrument used to test the mechanical properties of various materials, particularly their behavior under tensile (pulling) loads.

This type of testing is essential for evaluating the strength, ductility, and other mechanical characteristics of materials used in various engineering applications.

The primary function of a tensile testing machine is to apply a controlled, increasing tensile force to a test specimen until it fractures or deforms to a predetermined level. The machine measures the applied force and the resulting deformation or elongation of the specimen, providing data that can be used to calculate various mechanical properties, such as:

- Tensile strength: The maximum tensile stress a material can withstand before fracture.

- Yield strength: The stress at which a material begins to deform plastically (permanently).

- Modulus of elasticity (Young’s modulus): The measure of a material’s stiffness or resistance to elastic deformation.

- Elongation or strain at fracture: The amount of deformation or elongation a material can undergo before breaking.