Wikipedia summary: Aluminum bronze is a type of bronze in which aluminum is the main alloying metal added to copper, in contrast to standard bronze (copper and tin) or brass (copper and zinc). A variety of aluminum bronze alloy of differing compositions have found industrial use, with most ranging from 5% to 11% aluminum by weight, the remaining mass being copper; other alloying agents such as iron, nickel, manganese, and silicon are also sometimes added to aluminum bronze.

Where is Aluminium Bronze used?

Bearings, bushings, sealing rings, wear plates, valve components, turbines, landing gear parts, nuts, fasteners, propellers, aircraft, ship propellers, worm wheels, marine hardware, machine parts, machine tools, and other industries need to use these aluminum bronze accessories, it is used in a wide range of environments, in all walks of life and anywhere you can think of aluminum bronze alloys.

Some aluminum bronze is even stronger than low alloy steel, while most are stronger than stainless steel. Aluminum bronze maintains its strength in high-temperature furnaces and also at low temperatures.

Casting capacity of aluminum bronzes bushings.

Our current strength is the casting and machining of aluminum bronze bushings. Can produce aluminum-bronze bushings/bearings of size 60mm-6M, which also can cast tube/rod/plate can be customized.

Aluminum bronzes in Hydropower industry

The 1M-4M aluminum bronze bushing is the most convenient size, and it has been supplied to domestic and foreign hydropower plants for a long time, especially the hydropower units in the pumped-storage power station.

From the smelting of aluminum bronze materials to the casting, processing, and testing of bushings, we are all responsible for ourselves, and we have professional production lines.

Aluminum bronzes in Ship industry

The propeller made of aluminum bronze has amazing anti-corrosion (corrosion resistance) ability of seawater and the ability to prevent the growth of organisms in seawater. This propeller is generally cast in a vertical metal mold, which is completely different from centrifugal casting.

Metal mold casting has high precision requirements on-die inserts size, casting method, and casting temperature. Our aluminum bronze propellers and seals supply passenger and cargo ships, container ships, oil tankers, reefer ships, salvage ships, icebreakers, scientific research ships, etc.

Mechanical properties of aluminum bronze alloys

Aluminum bronze is a type of bronze in which aluminum is the main alloying metal added to copper, in contrast to standard bronze (copper and tin) or brass (copper and zinc).

A variety of aluminum bronze of differing compositions have found industrial use, with most ranging from 5% to 11% aluminum by weight, the remaining mass being copper.

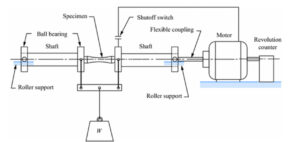

Research on Aluminum Bronze Bushing

C95400/JED10-3 alloys and C95500/JED10-5-5 are the most popular general-purpose aluminum bronze. There is a high demand for hydroelectric generating units, especially sealing strips, fastening rings, etc.

Abrasion resistance is in high demand. In important occasions where high strength, wear-resistance. and excellent corrosion resistance is required, aluminum bronze alloys have strong advantages and can resist wear and deformation.

Even in poor lubrication conditions, service life can be checked and maintenance costs reduced. Reduce friction, wear, and seizure. Has quite good heat resistance and welding performance.

- Excellent machinability and weldability for the fabrication of complex shapes and structures.

- Excellent abrasion and abrasion resistance.

- Resists fatigue and deformation when subjected to shock, shock, and vibration loads.

- Excellent ductility. Forgeable. Can be heat treated from the factory or can be heat treated after the market.

- Relatively low coefficient of friction. Antioxidants in seawater environment.

How strong is Aluminum bronze?

Here are performance parameters of aluminum bronze bushing:

| GB/T | ZCuAl10Fe3/JED10-3 | ZCuAl10Ni5Fe5/JED10-5-5 |

| ASTM | C95400 | C95500 |

| BESN | CC331G | C333G |

| HARDNESS | 100-130HB | 140-170HB |

| ELASTICITY MODULUS | ≈110KV/m㎡ | ≈120KV/m㎡ |

| TENSILE STRENGTH | 490-580Mpa | 490-580Mpa |

What copper alloys are there besides aluminum bronze?

Nickel aluminum bronze, Tin bronze, lead bronze, aluminum brass, steel-copper composite alloy materials, aluminum brass can be used as bushings. Other alloys according to low magnetic permeability, excellent resistance, low reactivity, high temperatures, wear resistance, corrosion resistance, and other properties.

- C95400 /JED 10-3 is the most popular general-purpose aluminum bronze alloy.

- It has higher yield tensile strength and tensile strength, good ductility and weldability, and excellent wear resistance, fatigue resistance, and deformation resistance under impact or overload than other bronze alloys.

- Applications: High-strength bearings, bushings, gears, worms, wear plates, valve seats, and guides.

- C95500 /JED 10-5-5 Aluminum Bronze alloys Recommended for heavy-duty applications involving wear, abrasion, and fatigue.

- The high-strength alloy has excellent yield strength, compressive strength, high hardness, and fairly high elongation.

- The addition of nickel provides excellent saltwater excellent corrosion resistance.

- Applications: High-strength bearings, corrosion-resistant parts, aircraft valve guides, and valve seats.

welcome visit our site: www.jiaerda.cn / www.jedheatexchanger.com