Bronze Bushing Casting Capability

Today around bronze casting, I will write an article.

First of all, it is necessary to declare one thing: bronze bushing casting is not a simple matter of smelting the material and then casting it. The technical requirements of the knowledge points are very strict and are all the key points to focus on.

- temperature

- material ratio

- chemical analysis

- strength

- air density

- hardness

- pore problems

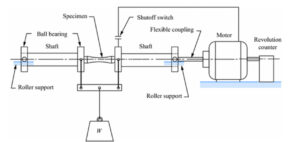

Our factory’s casting method categories

I know about our company’s bronze casting workshop:

- 70% for centrifugal casting

- 20% for horizontal continuous casting

- 10% for vertical metal mold casting

80% of the bronze bushings on the market are also centrifugal casting, because of the limitations of technology and equipment, there are more ones with a diameter of less than one meter.

Because bronze casting has certain technical difficulties, process capabilities, equipment capabilities and so on. Therefore, there are not many manufacturers of bronze bushings with a diameter of more than 1 meter that can be cast perfectly.

Some of the clients we are working with

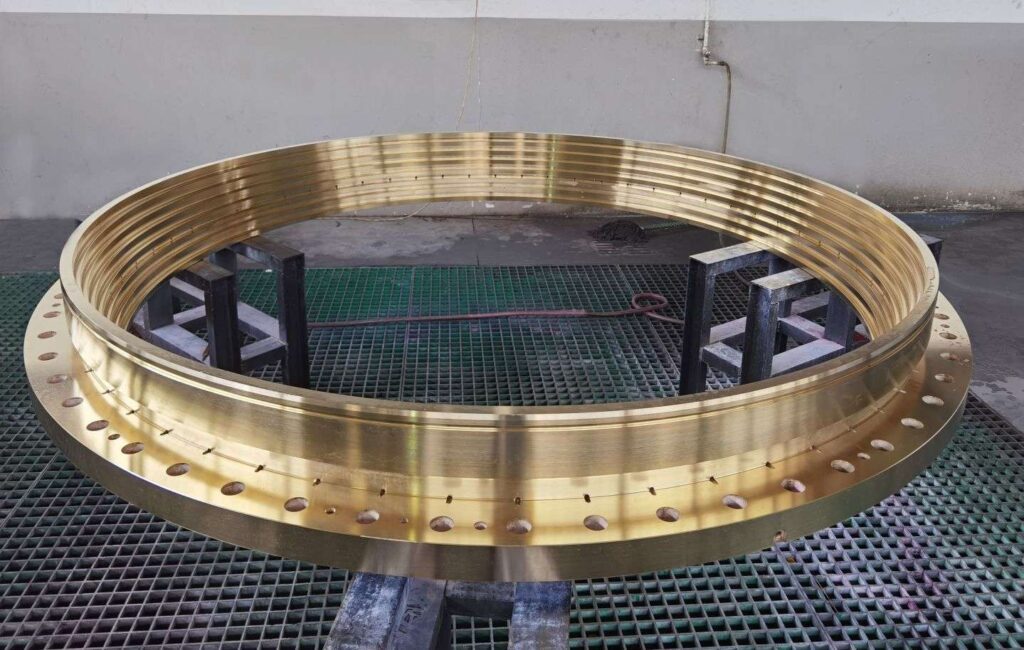

We have done the research and they have a fairly high scrap rate of bronze bushings, not to mention the successful production of bronze bushings with a diameter of 5 meters. What I’m proud of is that we are very mature in casting and processing such super-large bronze bushings, and our clients are also Fortune 500 or super-large projects.

Some of the projects we are working with

When our colleagues in the corporate operation department were shooting the video, they found that our company has a complete range of bushing molds, ranging in size from 60mm-5m. This full-size mold is a great advantage in meeting customer requirements, which can save you mold costs and speed up the production and delivery of bushings.

Another point, even if you have a 5m bronze bushing mold, smelting, casting, and precision machining are all difficulties that need to be overcome.

Relationship and advantages between products and projects

We have made statistics that 80% of bronze bushings with a diameter of more than 3 meters are used in hydropower units, and 60% of them are used in pumped storage power station projects. Bronze bushings have the advantage that plain bearings do not have at all, and are completely irreplaceable.

We were lucky enough to get some pictures of finished bronze bushings waiting to be shipped while we were taking photos in the workshop.

These bronze bushings have passed non-destructive testing for PT and UT. The non-destructive testing of bronze bushings is a necessary test. After the test is completed, a certificate of conformity will be provided to the customer. We also had the honor to photograph the company’s training session, if you are interested, I can share it with you.