Yes, we have upgraded the whole machining center in order to achieve higher precision and meet the higher requirements of the current situation.

What is a constant temperature workshop? Cold or hot?

A constant temperature workshop is a workshop with a constant temperature, which is most simply understood as an air-conditioned workshop. It needs to be constant temperature according to the technical work type, generally not too hot and not too cold. In a certain range to exclude this space of microparticles, harmful air, bacteria, and other pollutants, will be temperature, cleanliness, indoor pressure, airflow speed, airflow distribution, noise vibration, and other control in the demand range.

The constant temperature environment ensures that the machines, products, and testing requirements stored inside the workshop are maintained, so that the required cleanliness, temperature, humidity, and pressure performance can be maintained regardless of changes in external air conditions.

What are the benefits of upgrading a copper bushing machining shop to a constant temperature shop?

There are benefits in that it helps to protect the tooling used in the machining center from rust and corrosion due to high air humidity. There are a number of sensors in the machining center, and constant temperature and humidity in the shop also allow the sensors to maintain qualified accuracy. Precision instruments and equipment can only be qualified for production and testing if they are kept to a strict precision.

Does temperature have such a big influence on the profile size of copper bushings?

There must be an impact, copper follows the same natural material “thermal expansion and contraction”, under the same circumstances, the copper thermal expansion and contraction phenomenon is more obvious. Copper bushings, and copper seals because of the use of different environments, there will be a large size deviation.

For example, our company is in Zhejiang Zhuji at the “subtropical”, the use of copper bushings is in Tibet’s “highland cold”, so how can we ensure that copper bushings can reach the customer’s drawing requirements? At this time, the effect of the constant temperature processing workshop and the testing room comes into play.

What are the requirements of constant temperature for the workshop environment standard?

One is the production process on the environmental temperature and humidity requirements, the other is the production equipment on the environmental temperature and humidity requirements.

Temperature of constant temperature workshop

- Commonly used precision requirements: temperature 25 ± 5 ℃, humidity 65% ± 10% RH, mainly used in the general requirements of constant temperature and humidity workshop.

- Higher precision requirements: temperature 25±5℃, humidity 65%±5%RH, mainly applied to the higher requirements of constant temperature and humidity workshop.

- Special environmental requirements: low-temperature 5-18℃, high-temperature 30-40℃; relative humidity requirements less than 40% RH, relative humidity higher than 80% RH, mainly used in the special production process of manufacturing.

Is there any difference between the air-conditioning and constant temperature system of mechanical processing workshop and general civil facilities?

Of course there are differences, especially in the technical indicators of the control system is a big difference.

Because the precision machining workshop environmental control requirements are different, the production of the required processing environment is different, in the design of the air conditioning automatic control system requires the integrated use of computer monitoring, programmable controllers, intelligent sensors, industrial field bus, fiber optic communication and other technologies to achieve automatic control of the system, to ensure the reliable and stable operation of the air conditioning system.

Is it harmful to people to work in a constant temperature workshop for a long time?

No, constant temperature and humidity environments generally have no effect on the body. However, if you work in this kind of environment for a long time, it may lead to a weakened ability to adapt to changes in the external environment.

Therefore, it is recommended to have a certain amount of time of daylight exposure every day and to pay attention to exercise to enhance physical fitness. When entering or leaving the workshop, stay a little in the transition area to adapt for a few seconds.

How does a thermostatic air conditioning system consist?

The thermostatic air conditioning system is mainly composed of an air conditioning and refrigeration system, piping system, and automatic control system, of which, the workshop thermostatic automatic control system is the most important and basic part of the central air conditioning system of the entire joint workshop.

our central air conditioning system uses centralized central air conditioning primary return system. The whole air conditioning system uses nine air conditioning units for temperature and humidity control, in order to save costs, the system does not set up a special air conditioning and refrigeration room, airflow organization selected the louvered air outlet on the way back.

In order to ensure the quality of the entire workshop temperature and humidity control, the central air conditioning system uses a variable air volume air conditioning system.

How to manage the constant temperature workshop?

A good thermostatic control system not only needs good equipment but also must have excellent management. As the automatic control system of the air conditioning system is complex and the equipment is scattered, it is impossible to complete the operation of each air conditioning equipment if it is operated manually.

Therefore, the air conditioning control system must have a high level of automation, requiring the central control room in the system can be carried out and complete all operations.

How to manage the access control of the constant temperature workshop?

- In the scope of the company all the people in and out of the constant temperature workshop with access control card/password to enter and exit.

- When passing through the access control, close the door and leave in time.

- Non-staff are strictly prohibited to enter the thermostatic workshop area.

- Man-made, malicious damage to the access control system, need to bear the repair costs.

What cooling equipment is best for a constant temperature workshop?

General workshop cooling equipment, there are fans, ground sprinkling, fluorine air conditioning, environmental protection purification type water evaporation air conditioning, water temperature air conditioning, fan coils, wet curtain, and other methods.

In the hot summer, workshop cooling has become a major problem, some manufacturers use fans, ice, air conditioning, and fogging cooling methods, these cooling methods have certain effects, but also have certain shortcomings.

Factory workshop cooling method

- Fan cooling, has a certain effect, but the workshop itself is too high, and can not be very good cooling, wind cooling is to increase the principle of human epidermal moisture volatilization to cool down.

- And because the summer workshop temperature is too high, the wind blown by the fan is hot wind, blowing to the human body is higher than the temperature of the human body, even if the sweat can evaporate some, can reduce the temperature, but because the workshop temperature is too high resulting in the human body can not be completely cooled, so the fan cooling conditions is the air temperature is lower than the human body temperature, people can feel cool.

- Ice cooling is the use of ice liquefaction heat absorption principle, is the use of ice liquefaction needs to absorb the heat of the air, is the air temperature down, but because of the poor thermal conductivity of the air, resulting in ice cooling range is relatively small, if you want to use a large area, the cost, high problem.

- Fog cooling is also an effective cooling method, but because the humidity is too large, the production of machinery and the human body has a certain impact, so it is not suitable for workshop production use. It is a neutral cooling method.

The best method of both heat exhaustion and cooling, only the constant temperature workshop air conditioning cooling method can be well adapted to the workshop itself to produce a relatively large heat environment, suitable for the workshop and other sealed environment cooling.

What equipment is needed for constant temperature control?

General thermostatic control requires heating equipment and a temperature measurement probe. The principle is that the temperature probe detects the temperature, and decides whether the heating equipment needs to overheat, high temperature to stop heating, and low temperature to continue heating, here you can use PID regulation.

Do this algorithm, you can use the temperature control table or PLC, etc. This depends on the actual situation of the product, and equipment, you can choose the right probe for you.

PID temperature controller, a typical closed-loop temperature control system for controlling the temperature of the heating temperature zone (PV) to maintain a constant temperature setpoint (SV).

The system obtains the deviation value (EV) from the real-time temperature signal (PV) fed back by the temperature acquisition unit, and the deviation value is calculated and output by the PID regulator to control the heating power of the heat pipe to overcome the deviation and drive the deviation close to zero.

What specific thermostat equipment is needed?

- Temperature controller, such as temperature control table, of course, if the conditions can also choose PLC or microcontroller to do, you need to match – some temperature measurement sensors and heating and cooling equipment. Used to turn the electrical signal of the sensor into the temperature value we know, and can set some conditions, such as how many degrees below the start of the heating equipment, above how many degrees to start the cooling equipment.

- Temperature measurement equipment, such as thermocouples, and RTDs. Used to monitor the temperature, the temperature will be converted into electrical signals.

- Heating equipment is used to make up the temperature. If the year-round temperature is higher than the required temperature, you can do without it. According to the selected equipment to determine, some can be used with the air supply and water delivery, etc., try to achieve overall temperature stability, to avoid a hot area a cold area.

- Refrigeration equipment is used to cool down. If the year-round temperature is lower than the required temperature, can be used.

- Insulation is used for heat dissipation. For example, do outdoor insulation, etc.

- Some other materials, such as wire, etc., without specifying.

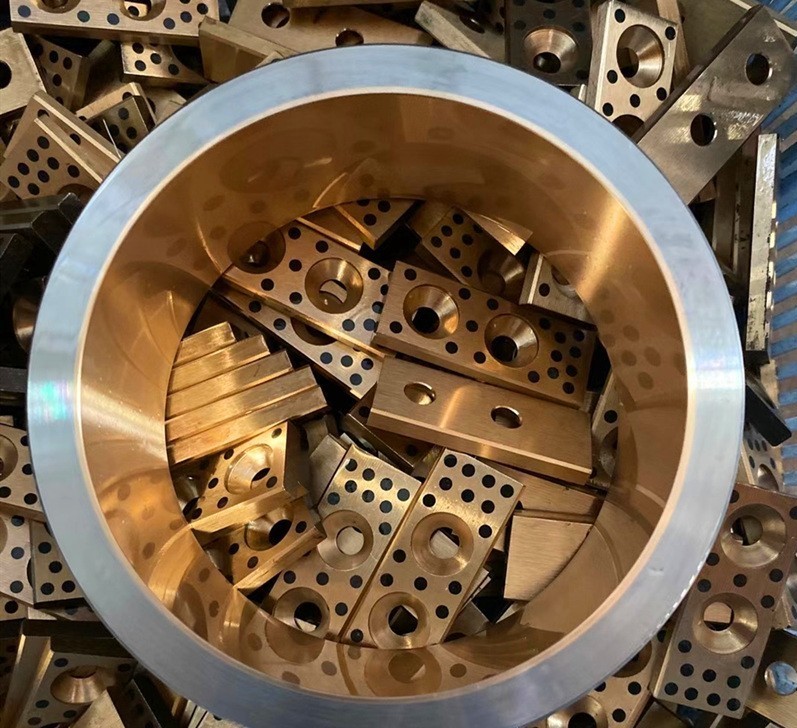

Do copper bushing manufacturers want constant temperature assembly?

Copper bushing manufacturers are also demanding higher and higher precision and quality of their products. In order to follow this trend, in addition to investment and training in equipment, and personnel, we have spared no expense in building a constant temperature and humidity workshop to ensure the processing accuracy of copper bushings.

At present, we have already realized a constant temperature workshop, and next year we will invest nearly 20 million in new workshops and new equipment (vertical lathe, gantry, Zeiss CMM). Constant temperature workshop renovation and management training are essential for the development of enterprises, which many domestic enterprises have not yet figured out.

High-precision copper bushing constant temperature manufacturing in Europe and the United States is the mainstream, the technology is also relatively mature. Foreign high-precision copper bushing manufacturing, from the beginning of parts processing in a constant temperature (generally 20 degrees Celsius), constant temperature assembly, constant temperature storage, until constant temperature use, to avoid copper bushings for a long time in a non-constant temperature state.

Why do we need constant temperature manufacturing?

Each process of machining requires the cooperation of the previous and subsequent processes in order to achieve the purpose of the process, similarly, constant temperature assembly also requires the previous and subsequent processes to ensure that the role of constant temperature assembly should play.

This is the case with these thermostatic assemblies. The ideal solution is to produce the parts at a constant temperature and to ensure that they reach the rated temperature by storing them at a constant temperature for a certain amount of time.

Is the constant temperature workshop to be 24 hours a day?

The workshop achieves a constant temperature 24 hours a day. Parts are at a constant temperature during the day and at a non-constant temperature at night, and the temperature of the machine parts has not returned to a constant temperature by the time they are processed the next day.

Copper bushings are not used at a constant temperature. Copper bushings sold to customers are not used at a constant temperature. Copper bushings made at constant temperature are deformed when they are not at a constant temperature, so the meaning of constant temperature manufacturing is lost.

Constant temperature workshop is not constant temperature. Workshop local area temperature is 20 degrees Celsius, some places will reach 25 degrees, strictly speaking, the temperature difference between the constant temperature workshop will not be greater than plus or minus 0.2 degrees. Please copper bushing factory really put the constant temperature assembly into practice, not just a publicity gimmick.

In fact, the general precision of copper bushings is not necessary to use constant temperature assembly technology, in the non-constant temperature state of the copper bushings most need to be stable, not high-precision, of course, to the assembly plant installed with air conditioning is the humanistic care of technical workers, but also help the management of the factory working environment, no need to criticize.

But the real high precision copper bushings must use the constant temperature manufacturing technology, not only the constant temperature assembly, our other workshops are also in the constant temperature transformation.

A requirement for constant temperature workshop how to make?

Precision copper bushings on the environment requirements are very large, not only requires indoor air humidity and can not be too large indoor temperature can not be too high, but also needs to be maintained in a stable range.

- The physical parameters of the workshop: length, width and height.

- Need temperature, humidity control range and precision: for example: 18 ~ 27 ℃ ± 0.5 ℃, 40 ~ 60% ± 5%, etc.

- Internal heat load, humidity load

- Geographical location (range of external temperature and humidity change)

- The location and space where the air conditioner can be installed, etc

Off-topic.

The constant temperature room in the factory needs to achieve a steady flow of fresh air, and the air conditioner also needs to create a flag to view window cleaning, fresh air flow, energy, comfort, and days for reference. Based on this professional data, it is also possible to improve and redesign more perfectly.

Sharing this article is not only for copper bushings needing a constant temperature workshop, but also for customers to share it to more people on our behalf when they visit our factory, which is also a quality service improvement.